Stuff We Oughta Know About RIMMED Baking Sheets

Have you ever noticed how rimmed baking sheets are one of those kitchen items you can turn to many times a day? We use them for baking cookies, biscuits, scones, jellyroll cakes, and for roasting oven fries and asparagus, and so much more. With wire cooling racks set inside, they're good for broiling or roasting meats and cooking bacon. And in prep work (such as holding breaded cutlets before frying), they’re also handy. A good rimmed baking sheet isn't just for baking—it’s a true kitchen workhorse.

“Good” is the key word when it comes to rimmed baking sheets. It’s hard time to find really good ones in most home-goods or cookware stores. Known as a half-sheet pan in restaurant supply stores, the real thing is made of heavy-gauge metal and measures 18x13 inches with a 1-inch rim all around. The closest thing typically found in retail stores is a flimsy, too-small 15 by 10-inch "jellyroll pan." Save your money and hunt for the real deal.

When hunting, you’ll notice there’s a wide range of quality to choose from. Not only are they not identical in materials, but there’s a big discrepancy in construction, too. Rimmed baking sheets are formed by a machine that presses a flat metal sheet into a predetermined shape, maintaining consistent pressure so the metal will flow in without wrinkling or cracking. They can be made from different alloys and gauges of aluminum, aluminized steel (a thin coat of aluminum over steel), or a tri-ply sandwich of shiny stainless steel with an aluminum core.

Professional chefs and bakers will all tell you that solid construction is more important than the choice of materials. A flimsy pan warps under high heat. I experienced this when I baked fries at 475°F. The oil pooled at one end of the sheet, as I made fries in a oven, which resulted in uneven browning of the potatoes.

Also, the thicker the pan, the better. A pan that is too lightweight can transfer heat too intensely, burning batch after batch of cookies. That’s when I go “grrrrrr.”

It’s important to understand, though, that warping can happen with any sheet pan, even a heavy-duty one, under certain conditions. Abrupt temperature changes are likely to result in warping, for example, if an empty, cold baking sheet goes into a hot oven. Similarly, having only a few scattered pieces of food on a baking sheet creates different temperature zones on the metal, with some spots where the pan is shielded from heat under the food, and others where it is fully exposed to heat. Different temperature zones contract or expand at different rates as they are heated, which causes warping.

Even though slight warping does not affect the pan's cooking performance, you do want to avoid it. So, to help prevent warping your baking sheet, cover the pan's entire surface with food as uniformly as possible, and heat the pan gradually rather than abruptly.

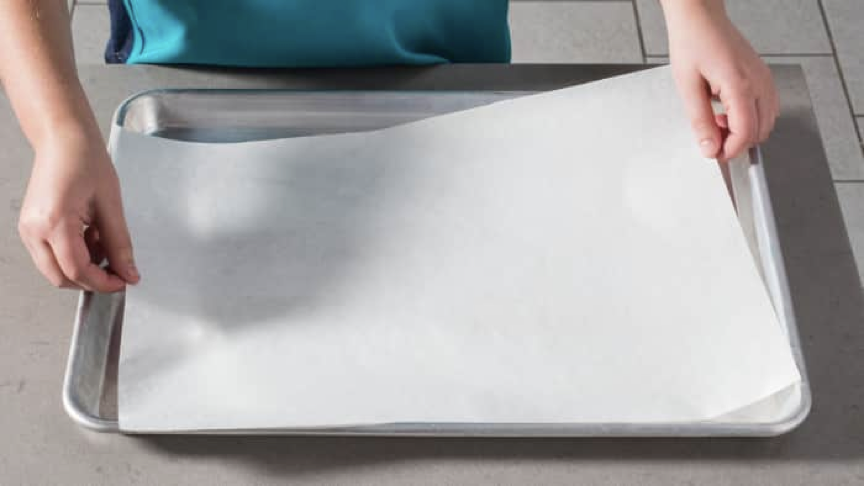

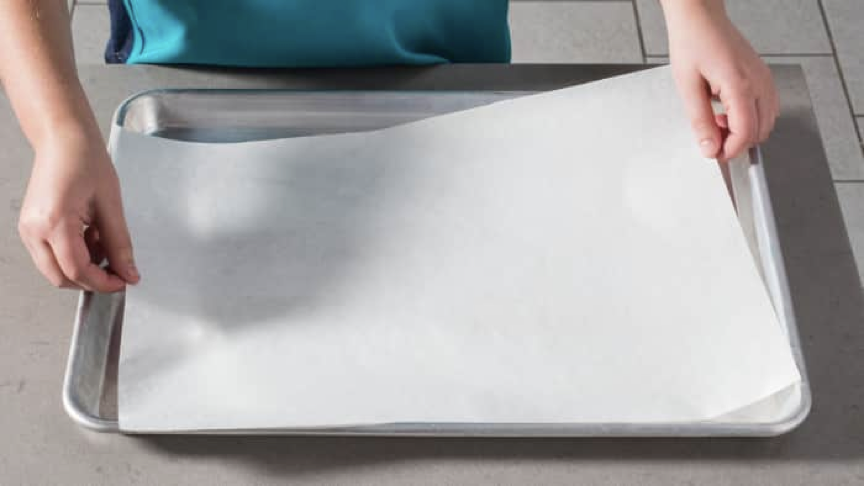

And for super protection to the pan’s surface, consider laying parchment paper in it, rather than greasing the pan.

This way the clean-up (if there is any) is easy and you’ll never see any burned-on grease build-up, which is such a pain in the neck to clean.

Some cooks swear by the silicon mat—the Silpat. After each use you just wash it and store it away until you need to use it again.

Finally, using a wire grid cooling rack inside the sheet pan can help distribute heat better than cooking meats directly on the pan surface.

These extra little steps will keep your pan looking nicer and prolong its life—it’s just stuff we oughta know.

blog comments powered by Disqus

“Good” is the key word when it comes to rimmed baking sheets. It’s hard time to find really good ones in most home-goods or cookware stores. Known as a half-sheet pan in restaurant supply stores, the real thing is made of heavy-gauge metal and measures 18x13 inches with a 1-inch rim all around. The closest thing typically found in retail stores is a flimsy, too-small 15 by 10-inch "jellyroll pan." Save your money and hunt for the real deal.

When hunting, you’ll notice there’s a wide range of quality to choose from. Not only are they not identical in materials, but there’s a big discrepancy in construction, too. Rimmed baking sheets are formed by a machine that presses a flat metal sheet into a predetermined shape, maintaining consistent pressure so the metal will flow in without wrinkling or cracking. They can be made from different alloys and gauges of aluminum, aluminized steel (a thin coat of aluminum over steel), or a tri-ply sandwich of shiny stainless steel with an aluminum core.

Professional chefs and bakers will all tell you that solid construction is more important than the choice of materials. A flimsy pan warps under high heat. I experienced this when I baked fries at 475°F. The oil pooled at one end of the sheet, as I made fries in a oven, which resulted in uneven browning of the potatoes.

Also, the thicker the pan, the better. A pan that is too lightweight can transfer heat too intensely, burning batch after batch of cookies. That’s when I go “grrrrrr.”

It’s important to understand, though, that warping can happen with any sheet pan, even a heavy-duty one, under certain conditions. Abrupt temperature changes are likely to result in warping, for example, if an empty, cold baking sheet goes into a hot oven. Similarly, having only a few scattered pieces of food on a baking sheet creates different temperature zones on the metal, with some spots where the pan is shielded from heat under the food, and others where it is fully exposed to heat. Different temperature zones contract or expand at different rates as they are heated, which causes warping.

Even though slight warping does not affect the pan's cooking performance, you do want to avoid it. So, to help prevent warping your baking sheet, cover the pan's entire surface with food as uniformly as possible, and heat the pan gradually rather than abruptly.

And for super protection to the pan’s surface, consider laying parchment paper in it, rather than greasing the pan.

This way the clean-up (if there is any) is easy and you’ll never see any burned-on grease build-up, which is such a pain in the neck to clean.

Some cooks swear by the silicon mat—the Silpat. After each use you just wash it and store it away until you need to use it again.

Finally, using a wire grid cooling rack inside the sheet pan can help distribute heat better than cooking meats directly on the pan surface.

These extra little steps will keep your pan looking nicer and prolong its life—it’s just stuff we oughta know.

Sources:

- www.simplejoy.com

- www.thefrugalgirl.com

- www.swissdiamond.wordpress.com

- www.americastestkitchen.com

- www.williams-sonoma.com

Alice Osborne

Alice Osborne

Weekly Newsletter Contributor since 2006

Email the author! alice@dvo.com